XYZ

X to XYZ

2014

Competition: Honorable mention

Stuttgart & Graz

Concrete Design Competition

In collaboration with:

Nikolai Hanke

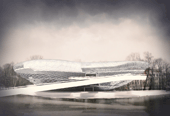

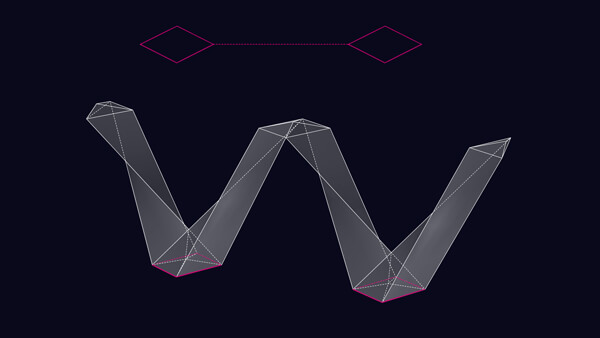

The aim of our design process was to develop a single element which is able to create a variety of spaces when it‘s multiplied. Therefore we had the claim to design the element for extensibility in three dimensions. Accordingly also the connection of the elements plays an decisive role. The result is an intelligent structure with an high aesthetics in consideration of structural-physical, constructive and economic conditions.

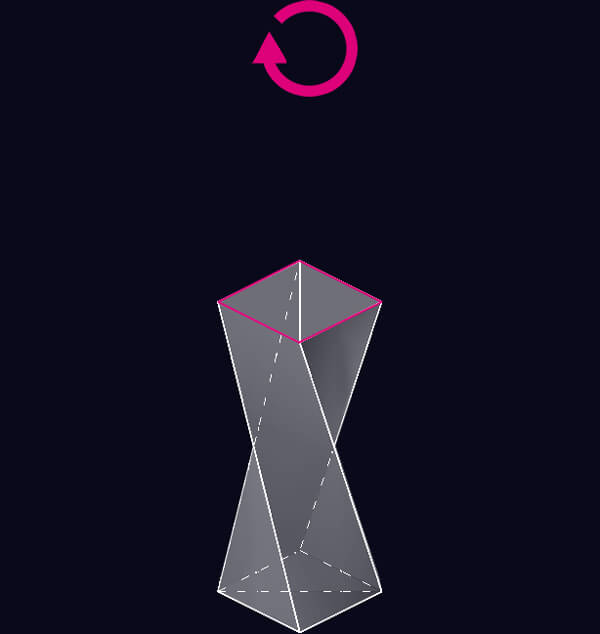

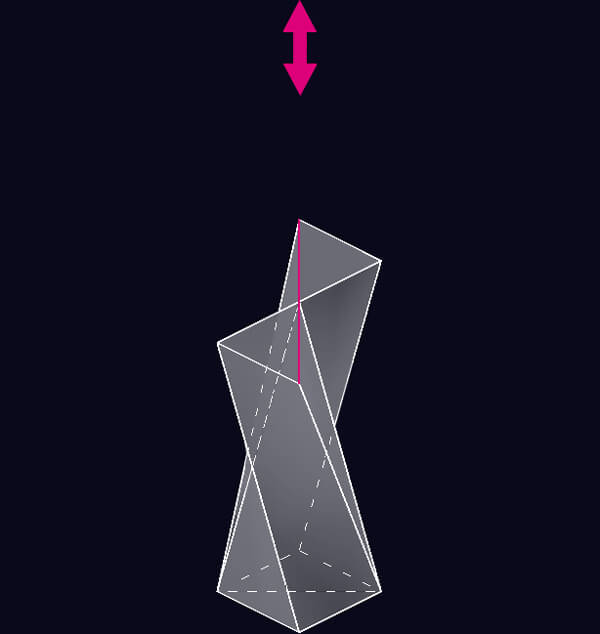

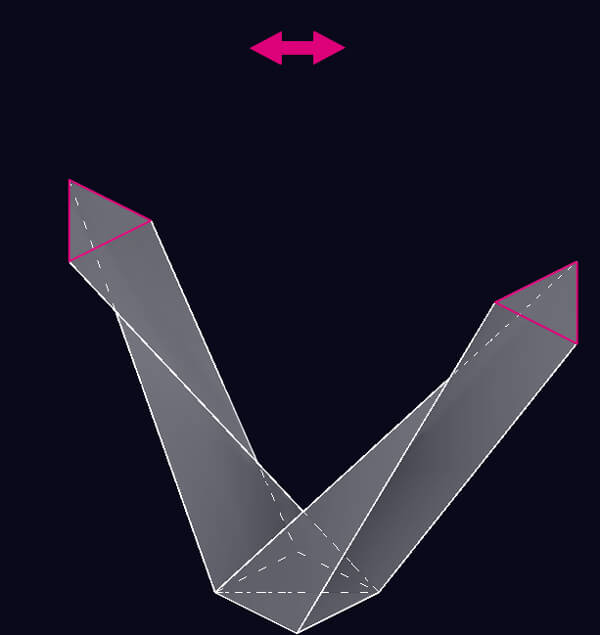

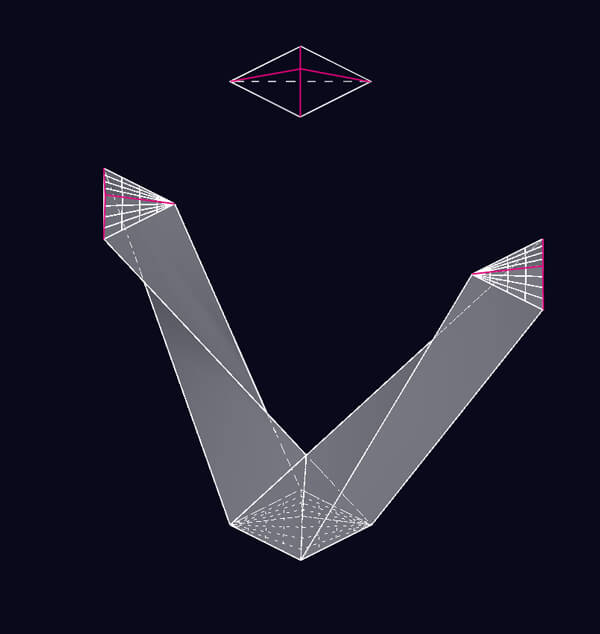

1. Shape

The element is generated by a systematic modification of a single cuboid. This creates an efficient and intelligent module which combines smart technical knowledge and aesthetic design.

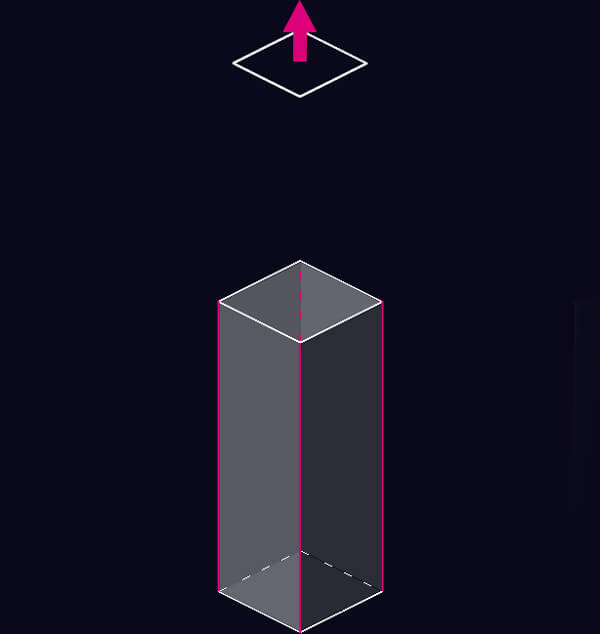

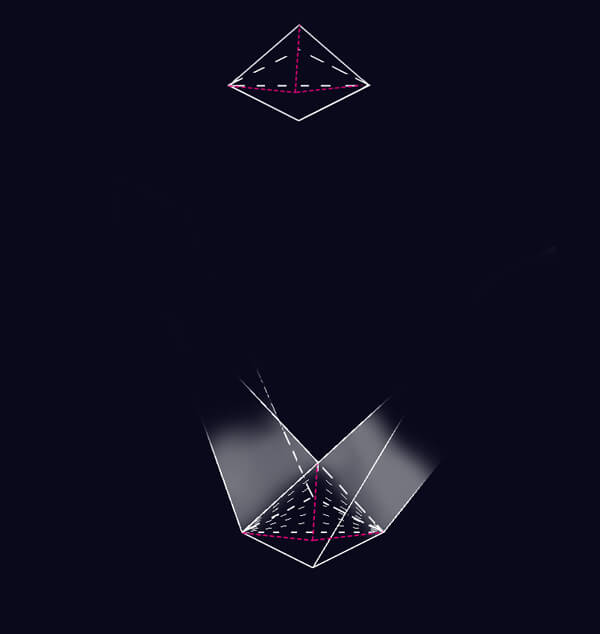

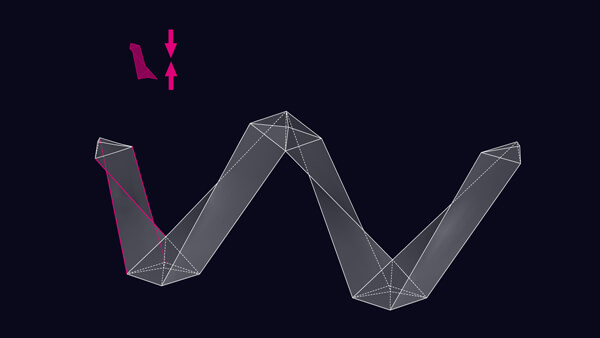

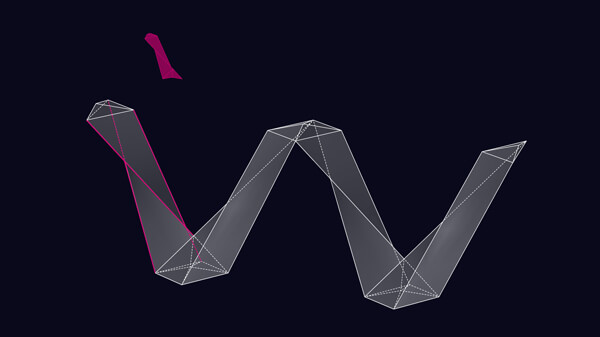

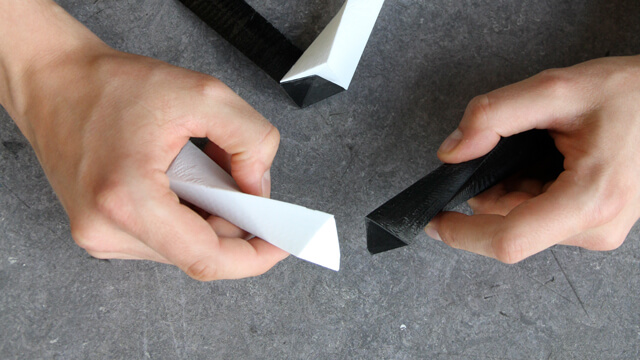

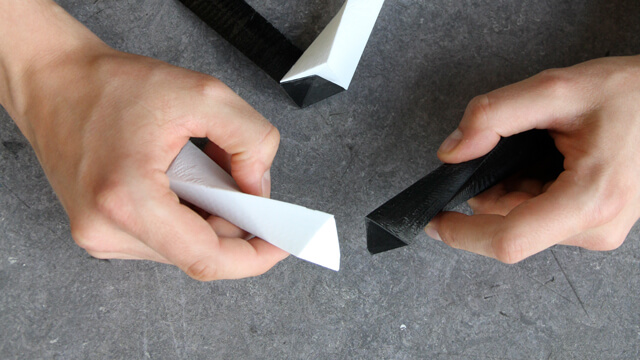

2. Connect

For a quick and logical assembly an easy connection point is essential. This point is made out of positive and negative pyramids to keep the design clear and to achieve a better bonding surface by forming a lager bedding pad. All elements consisting of a 1/4 of a positive pyramid on top as well out of 1/4 of a negative pyramid at the bottom. The standardisation of the connection point speeds up the assembly by creating less errors. To assemble one final connection point you need to glue four elements into one module which will create a big X.

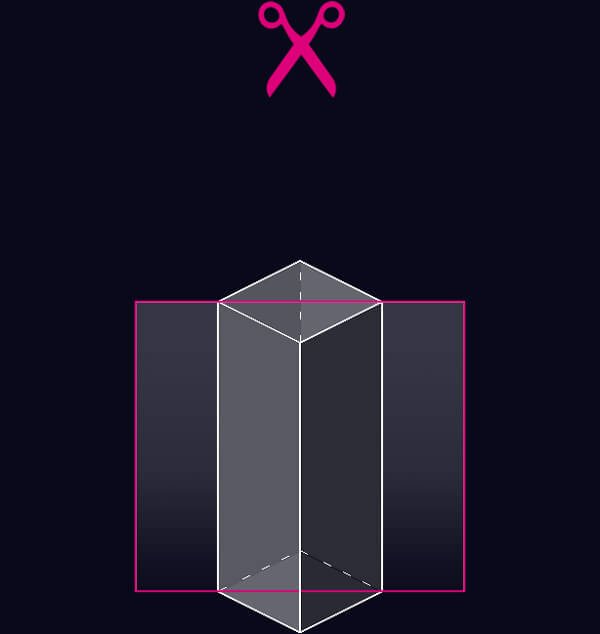

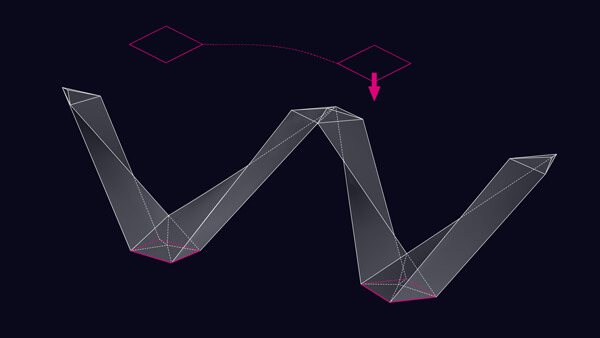

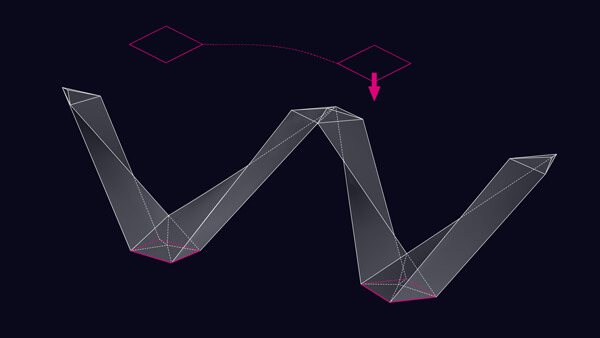

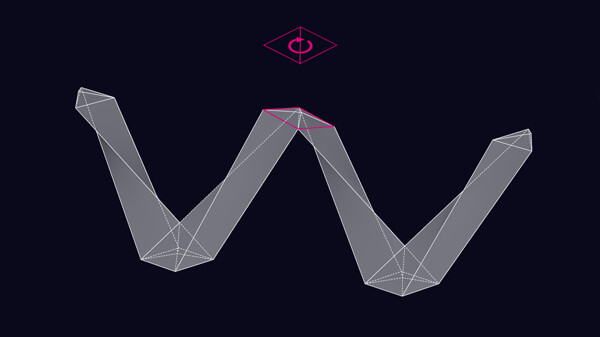

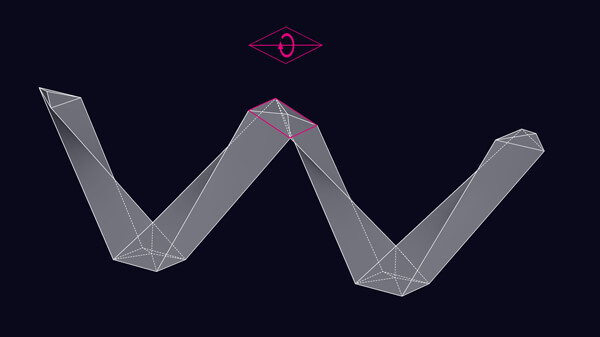

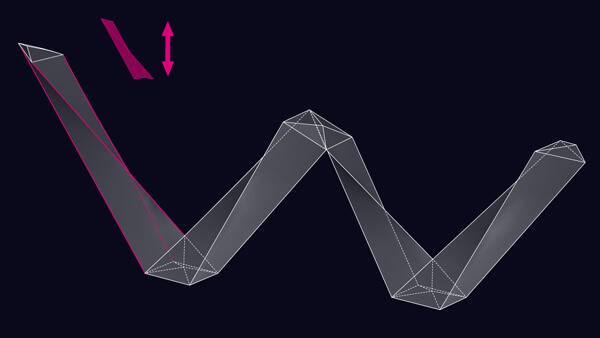

3. Set parameter

You can achieve nearly every design and structure by adjusting specific parameters. This is possible by tilting and bending the bedding pads as well as scaling and moving the single elements in the datum plane. These adjustments won´t change the monolithic and uniform appearance of the structure.

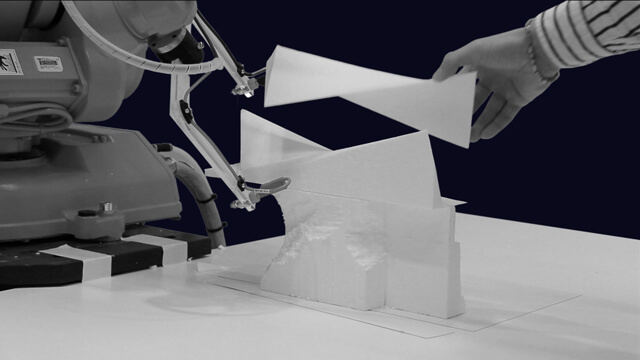

4. Realize

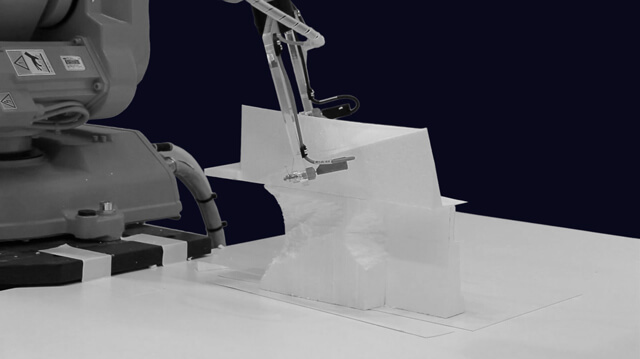

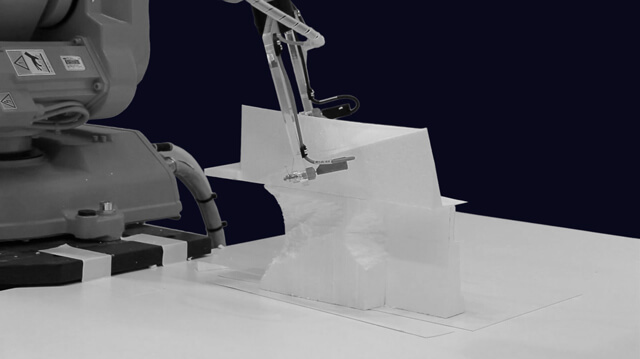

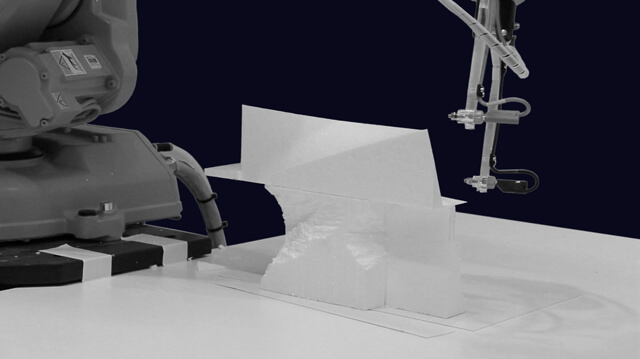

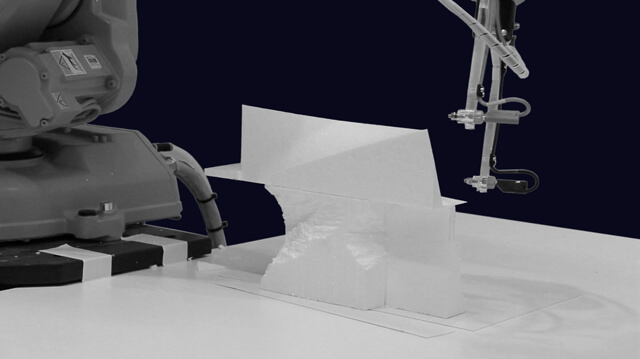

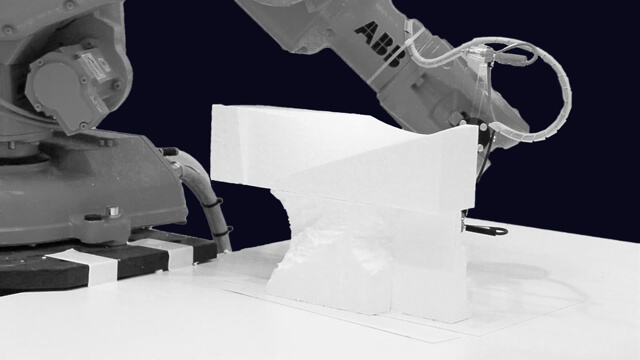

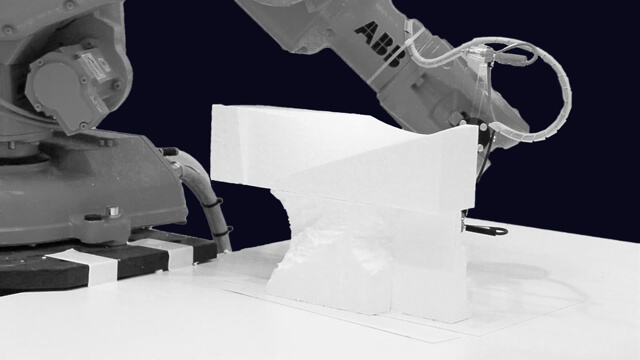

By using robotics the production of many different elements, made out of XPS, is very fast. In factory these single items will be glued together to an X and coated with high performance, small-grained sprayed concrete. A carbon fiber mesh will be placed in the concrete to minimize thermal tension cracks and damage caused by kicks. This method is grate for high load carrying systems.